Cultivation Facility Design Rules of Thumb

By Aaron Mullins, Systems Coordinator at Next Big Crop

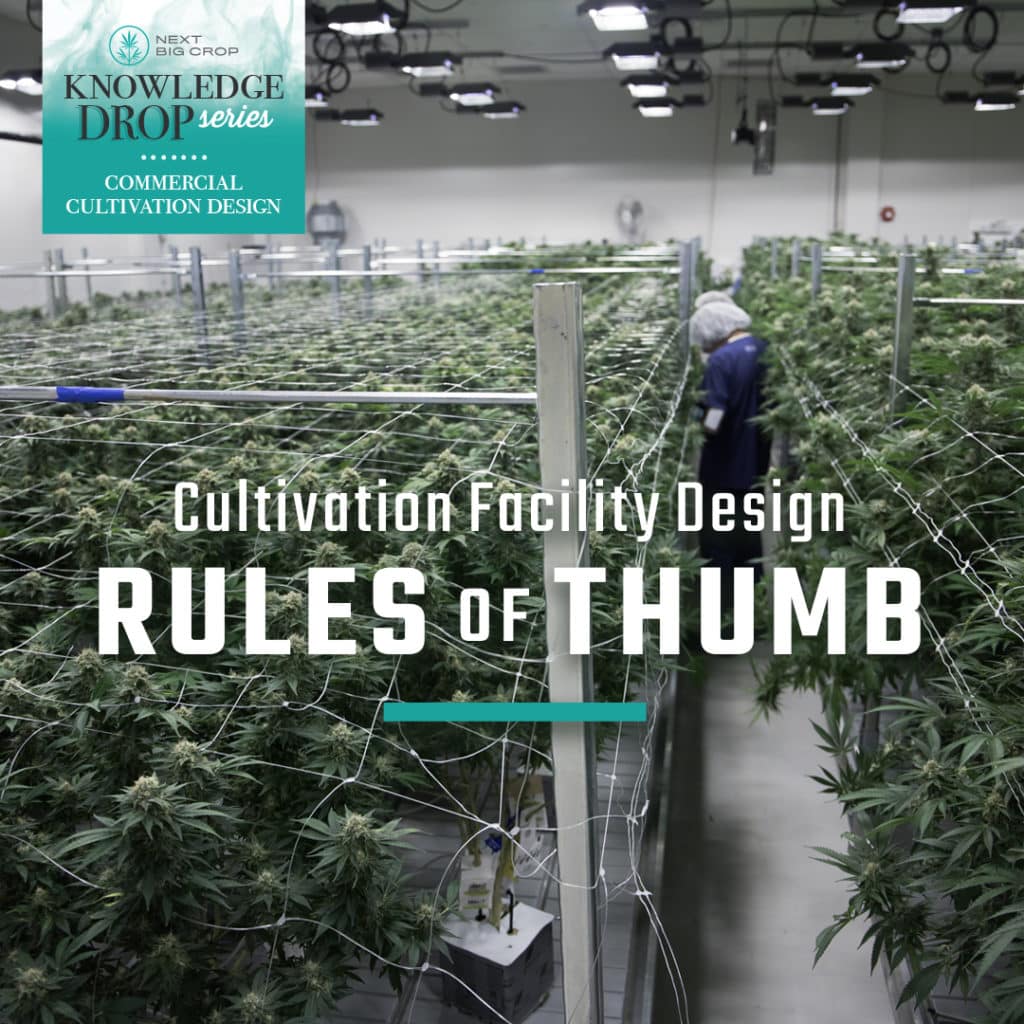

It’s no secret that any cultivation business needs a world-class master grower steering the ship. But perhaps equally as important as your head grower is your growing facility. To attract the most-talented people and set them up for maximum success, you need a cultivation facility designed for maximum efficiency. Here are five key rules of thumb to keep in mind when designing your grow space.

Location, location, location

Location is your central jumping-off point when building out your cultivation space. It impacts almost every aspect of your design and buildout—so it’s critical to carefully weigh all your options. It might seem obvious, but believe me, I’ve seen some very smart people sabotage themselves right out of the gate by choosing a location poorly suited to their needs.

There are plenty of factors to consider when sussing out location. For starters, are you building from the ground up or retrofitting an existing structure? Will you have access to adequate power? What about water? And what are you going to do with your wastewater? The answers to these questions and others often lead back to federal, state and local codes. So make sure you’re fully aware of all applicable regulations before settling on your location.

More height, more light

I’ve never met a grower who wanted shorter ceilings or less lighting space. Dark rooms and low ceilings are a massive challenge for growers. It’s very difficult, if not impossible, to produce top-quality flower in cramped spaces with no room for proper lighting.

Space, even vertical space, is always precious, and investing in higher ceilings whenever possible pays long-term dividends. And don’t forget: Making your growers’ lives easier by investing in adequate grow space helps keep them from leaving for greener pastures.

Consistent flower room size

It’s important to think about how the design of your cultivation facility impacts day-to-day operations. Everything builds from the flower rooms, and ideally, your flower rooms should all be the same size with the same canopy space.

Trust me, this one design feature makes life a lot easier at every step in the production pipeline. Planning out your vegetation rooms and your drying and curing areas is much simpler—with far less room for error—when you establish consistency across your flower rooms.

Your business is complicated enough already, so don’t compound that with an inherently lopsided workflow.

Embrace your automatic logging robot overlords

Were your grow rooms all within the right temperature and humidity range at 3 a.m. last Wednesday? That question might be more important than you think, and the only way to know for sure is through automatic logging technology. Relying on manually recorded input for your grow-room vitals leaves you subject to all our human flaws: forgetfulness, sloppiness, fatigue and more. Record that data automatically 24/7.

You want to give your growers as many good tools as you can. These will save time, make for better-informed decisions and keep your employees focused on what they do best.

No substitute for a strong team

It doesn’t matter how awesome your facility is if you don’t have talented growers on staff to make the magic happen. Your cultivation-facility design will help you get the most out of your team, but it won’t compensate for lack of expertise or cooperative teamwork. Never forget that your people are your greatest asset.

The best growers have plenty of options as to where they want to work, and they’ll be looking for operations that are thoughtfully planned. Building out your facility with your growers in mind helps attract the talent you need and equips them with the tools they need for optimal results.

If you’re ready to build out a cultivation facility that fuels your success, give us a call at 720-750-7022 for a free consultation.