Proper packaging and labeling are a critical part of any cannabis business

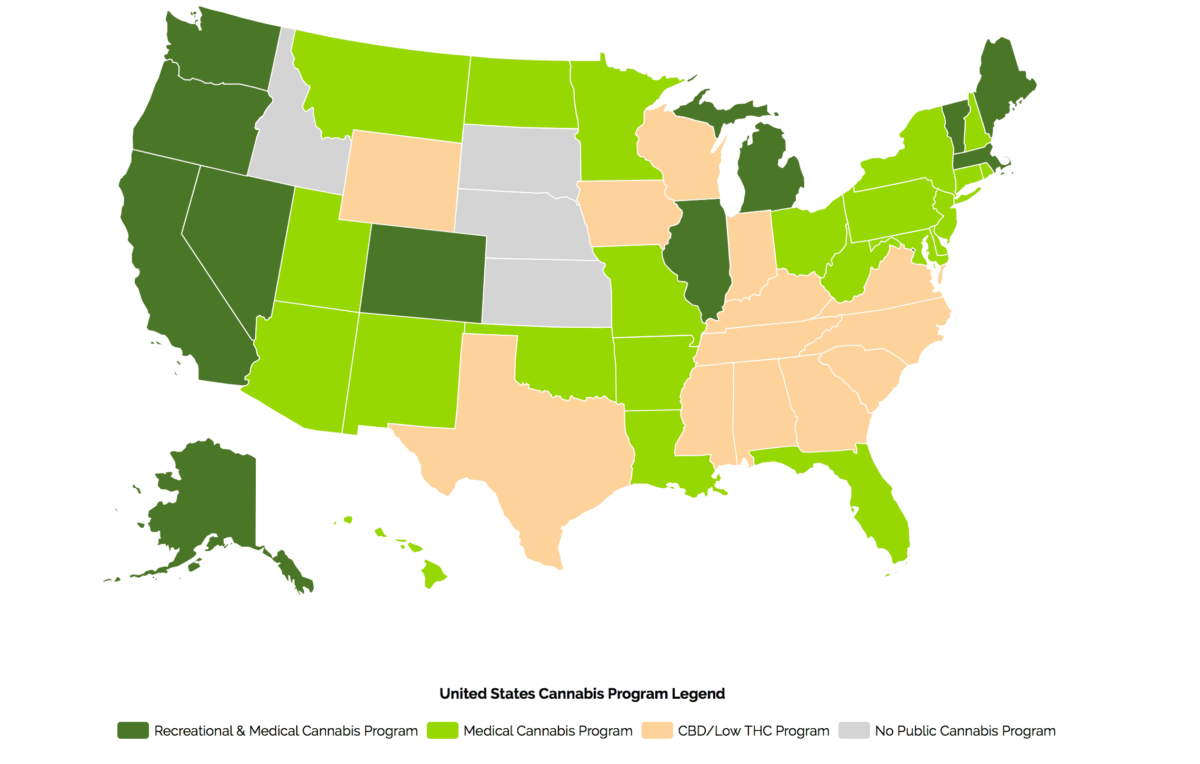

Proper packaging and labeling are a critical part of any cannabis business, each state with its regulations and guidelines. Check out the downloadable documents for each state’s requirements. As the industry grows, there are more product brands on the market competing to outsell one another. Proper packaging and labeling will help ensure that your product makes it to the dispensary shelf. High quality, unique labels catch the attention of individuals, and retailers often reserve better shelf location for brands that sell well. Ten seconds is all a brand gets to grab the consumer’s attention before they pass over the product.

To be successful in this market it takes front end investments in packaging and label design. When at a show, it is important to clearly explain why your product or service is superior to competitors. If you are ever at a show, stop by The House of Custom (THC) Solutions booth and ask questions about the labeling process. These are the top five questions they often answer for their customers…

- I only need cheapest paper labels, please!

- Cheap paper labels are not saving you money, because they often need to be replaced and can fall off completely.

- Adhesive and substrate to match your unique packaging can come with a higher cost but having your brand and compliance information available when it counts is worth it. We can ensure your labels stick to products under severe conditions, like freezers!

- I do not need anything too flashy.

- A company and brand only get 10 seconds to make an initial impression on a consumer. That is the equivalent to checking a notification on your smartphone.

- Branding is everything in recreational cannabis markets. Retailers often reserve better shelf space for more visually attractive products. Consumers often choose products with higher perceived quality, a message carried by product packaging and labeling.

- What is the difference between using paper vs poly labels?

- Semi-Gloss paper is the most cost-effective label; however, you get what you pay for

- They are not water resistant

- The labels tear easily

- Nearly impossible to peel off in one piece and leave behind a sticky residue

- Poly or BOPP labels cost more to invest in but provide your brand with better quality

- Water resistant

- Has a protective laminate layer

- Peels in one piece not leaving a sticky mess behind

- Semi-Gloss paper is the most cost-effective label; however, you get what you pay for

- Tamper tape is cheaper than void labels, why should I switch?

- While initially tamper-tape is cheaper and seems like the better option to go with until an order is rejected by the retailer because the tape has started to peel off jars and pre-roll tubes. Now you are spending more money to get it retail ready a second time or wasting product that must be disposed of.

- Tamper void labels are certified tamper-evident, adhere to any shape, size, and material and can be used to display lab analysis data. Plus, as a bonus, they provide more space to brand the product.

- Why are your labels more expensive than some of the competitors?

- Our service, support, guidance, and design process are structured on a one on one service methodology, providing a customized product solution.

- We produce high end materials, high quality prints that do not fade or smear.

Hello, I am trying to obtain the documents for each state’s packaging requirements, but it keeps saying that the site cannot be reached. Can you email me the documents please. Also, do you know which medicinal states require white packaging only?