Anatomy of a Washdown Duty Stainless Steel Air Circulator

So we caught your attention with “anatomy”! Sorry but from our point of view the anatomy / construction is nearly important as the anatomy of some other things!

Why should you care? Because knowing how a Stainless Steel Washdown Air Circulator is built will give you the basis to decide if one is right for you.

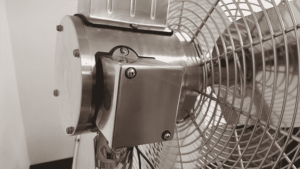

At right is an overall picture of a pedestal unit. Be it a wall mount or a pedestal mount the “fan head” is identical. As you might suspect, the “head” is composed of the motor, propeller, and guard.

As is often said, “the devil is in the details” and so are the reason why you should have a Stainless Steel Washdown Duty Air Circulator.

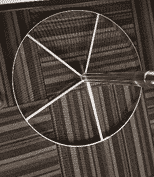

So starting at the bottom and working up, at left is a photo of the pedestal base. Notice that unlike a standard air circulator, the Stainless Steel Washdown Duty Air Circulator uses a five spoke open design that is slightly elevated from floor level on pads. The reason it is designed like this is to assure that you don’t have material hiding below the base. If material isn’t there you don’t have a hidden area for bugs and mold to hide either! And like the balance of the unit, the base is constructed of electropolished stainless steel and minimizes cracks and crevices in which dirt can hide.

The pole which connects the base to the head is like the balance of the unit electropolished stainless steel! In order to make it more shippable, it arrives in two pieces, but the pieces overlap (top over bottom) in such a way to keep water or material out of the unit. Unlike a standard air circulator, the pole is not height adjustable. How come? Because in an adjustable pole design one portion nests inside the other and it presents a real sealing problem not to mention the potential for trapping material inside when the pole is adjusted. You can’t have everything!

At the top of the pole is the motor which is part of the “head” assembly.

“Look Ma No Holes!” While a somewhat childish statement; it is none the less a very important feature. There are no holes for moisture or material to get into the motor

and there are special seals on the motor shaft to equally keep these problems from entering the motor in that fashion. Even the conduit box and the enclosure for the capacitor are stainless steel, gasketed, and impervious to water or dirt. Technically this is known as a “totally enclosed non-ventilated motor” with IP69 design.

Why? Aside from the fact that growing operations are constantly humid and moisture that enters a motor will quickly destroy the motor (the sensitive parts are usually the bearings where just the tiniest speck of rust will quickly destroy them) – having a motor with holes (an open motor which is standard on many commercial / industrial) air circulators prevents the unit from being thoroughly cleaned. Did you notice the “washdown” in the name? You can quite literally take a hose to this unit when you need to sterilize!

One last thing about the motor – the standard unit comes without a cord. I know, the inexpensive air circulators come with a cord! Here is why the Stainless Steel Washdown Duty does not; in order to maintain sealing of the electrical connection as it enters the conduit box the preferred method is to actually use conduit to bring the electrical supply to the unit. Cords are possible and can be used but they need to be watertight which requires a special cord assembly. Here is the tough bit – unlike normal power cords used on most everything, watertight cords and plugs are not standardized. One companies cord / plug does not fit another’s! So your plugs need to match your receptacles. Since we have no way of knowing what receptacles you might have we can’t supply the plugs. And since we have no idea whether you will use a cord or semi-rigid, or rigid conduit we don’t supply the cord either.

Next in line is the propeller which is connected directly to the motor shaft. Highly electropolished it will resist build up of material on the blade. Please notice that I said “resist”. It is not immune from having dust build up. We wish there was a way to make it immune, but we haven’t found that solution – yet! The nice thing, because the entire unit is designed to be sprayed with a hose it is quite easy to periodically clean the blade preventing that dust build up becoming a problem.

And finally, the guard. Like the balance of the unit it is constructed of stainless steel. It also meets OSHA standards.

We could have saved a significant amount of money by constructing the guard of normal steel wire rod and then powder coating it like with we do with some standard industrial air circulators.

I know, saving money is good but there are times when in the end it might not save money at all. Contamination! You can make quite a satisfactory powder coated guard for washdown duty (and in fact we do for our panel fans which are mounted high above traffic areas). But sooner or later you are going to bump into the guard on your air circulators! We know, we have seen what they look like after a few years of service. The problem with powder coating is that when the wire flexes the coating may chip. Where will the chip go? We have no earthly idea particularly if the unit is operating. There is a reason that many / most grow operations have people wearing lab coats or bunny suits isn’t there? Perhaps it is because it is a happy operation where they like to think it is Halloween every day, but we doubt it. It is because of contamination and the same reason that the guards of the Stainless Steel Washdown Duty air circulator are made of solid stainless steel.

Hopefully you now know where the “devil” is hiding and why your grow operation should have Stainless Steel Washdown Duty Air Circulators.

Contact aGROair sales representative and talk with them about your space and what is recommended.

www.aGROair.com / [email protected] / 517-449-7602