About the Numbers: Cannabis Quality Assurance Testing

One of the most controversial components of the implementation of recreational, adult-use cannabis in Washington and other states is mandatory cannabis quality assurance testing. Inconsistencies in methodologies of implementation, value of required reported information, and even inherent conflicts in the marketplace have all added to the controversy around the process.

The Washington State Liquor and Cannabis Board (WSLCB) has implemented a structure for Good Laboratory Practices in I502 quality assurance testing labs, and there also exist obligations of reporting requirements, integrity, and oversight. As the relevant legislation, WAC 314-55-102, states, “A lab must become certified in all fields of testing prior to conducting any testing or screening in that field of testing”. The basic credentials for testing laboratories are administered by Approved Proficiency Testing programs.

There exist 7 primary fields of testing and different types of products have specific testing requirements. For example, flower product that will not be extracted does not require heavy metals screening, or residual solvent screening. Likewise, concentrates that will be processed further in some way before reaching a market-ready state are called intermediate products, and these do not require foreign material inspection.

Potency Analysis

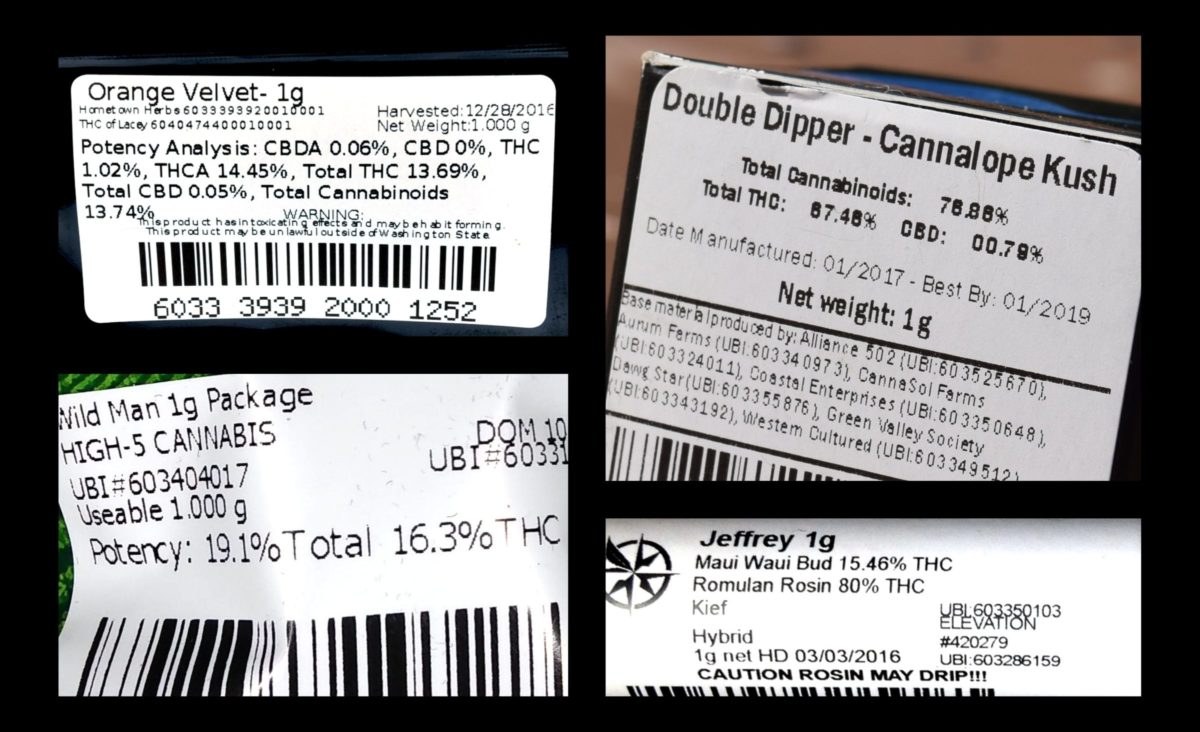

The numbers associated to cannabinoid content are often controversial. Some consumers rely on the listed numbers on cannabis packages, yet often industry experts find these numbers to be relatively uninformative and often detrimental to the overall cannabis marketplace.

Certified labs test and report many cannabinoids. THCA, THC, total THC, CBDA, CBD, and total CBD. There are regulations for how total THC and total CBD are calculated, which are generally accepted good practices, relevant to the mass fraction differential in decarboxylation process that changes THCA or CBDA to THC or CBD. In actuality, cannabis flower is incredibly difficult to consistently test for potency.

Moisture Analysis

Ask any grower and just about any consumer, the moisture of cannabis is critical. Cannabis moisture affects virtually all the market appeal aspects of this consumer good. Shelf-life, product color, intensity of effects can all be affected. Also, this addresses more critical aspects of a consumable good such as minimizing the potential for development of mold or allow other contaminant organisms to flourish.

Foreign Matter Screening

This is an interesting component, designed to ensure consumers receive the advertised amount of product and ensure the safety of consumers. In this case, a sample may only contain 2% or less of seeds or other foreign matters. Also, a limit of 5% of stems at 3mm or larger diameter. This is an clear consumer protection and indicates forethought in the implementation of this regulation.

Microbiological Screening

Two types of microbiological components are tested for in this field. Enterobacteria – bile-tolerant gram-negative bacteria – are limited at a rate of 10^4 in plant material or 10^3 in extracted product. Also, pathogenic strains of E. coli and Salmonella are tested for at a zero tolerance rate in 1 gram of tested material

Mycotoxin Screening

These screenings detect a secondary metabolite produced by fungi. Mycotoxin is highly toxic and can cause disease and long-lasting illness. There are a variety of types of Aflatoxin or Ochratoxin allowed at a maximum of 20 μg/kg.

Residual Solvent Screening

This field of screening is required for all extracted cannabis products. A wide variety of residual solvents are allowed in these products, and cannabis quality assurance labs must test for a variety of solvents, with maximums generally set at 5,000 ppm for class three solvents, 50 ppm for class two solvents, and 2 ppm for class one solvents. Labs test for a minimum of 15 common solvents.

Heavy Metal Screening

Heavy metals are a cause for concern in all consumer products. Inorganic arsenic, cadmium, lead, and mercury are all required in this category of testing.

Overall, considerable consumer protections are afforded by implementation of these cannabis quality assurance testing requirements. There are also additional costs for producer/processors, and there exists an inherent potential for inflation of numerical values. Often, in the actual marketplace, higher cannabinoid numbers result in more product purchased and at a greater cost. In general, there can be improvements in this process, but consumers seem to be generally well protected and oversight bodies can be informed by these rules.

By: Michael “the Aging Ent” Schroeder owner, Green Owl Media

Sources:

WAC 314-55-102 http://apps.leg.wa.gov/wac/default.aspx?cite=314-55-102

WSLCB Good Laboratory Practice (GLP) Checklist – https://lcb.wa.gov/publications/Marijuana/I-502/GLP-Checklist-v2.pdf

Approved Proficiency Testing Programs https://lcb.wa.gov/sites/default/files/publications/Marijuana/Labs/Approved-Proficiency-Testing-Programs-3-27- 17.pdf