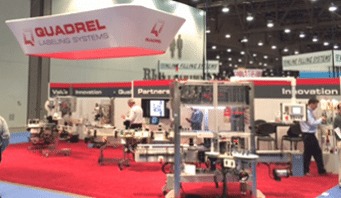

Quadrel

The world is entering a new manufacturing era, that of SMART FACTORY AUTOMATION.

Quadrel Labeling Systems is on the forefront of tying Smart Engineering & Smart Machinery to Smart Processes & Smart Organizations.

It is now possible, via the internet, to monitor the productivity of an entire factory or any part of that factory in real time from anywhere in the world.

Software changes or system adjustments can be made instantaneously and tied back to the IT system.

Not only can the operating system be monitored and adjustments made, but cameras may be installed to remotely confirm the success of the changes.

This is only the beginning, the future is limited only by our imagination.

Originally established in 1968 as a Division of Avery Dennison, Quadrel became independent in 1989. We offer a broad range of application equipment machinery, from simple tabletop units to sophisticated, zero-downtime mainframe systems.

We moved into our new state-of –the –art facility at 7670 Jenther Dr. Mentor, Ohio in 1995. We have undergone two major expansions since then. All of our equipment is designed and built in this facility. Mentor is approximately 30 miles east of Cleveland, Ohio.

With a labeling system for every application from tabletop units to high speed rotary systems, we know that the most important step is listening carefully to you. Only after we understand your business as a partner are we able to provide you with a perfect labeling solution.

Quadrel Labeling Systems’ Partners

Providing a comprehensive, capable and elegant solution for our customers often requires the products and support of multiple suppliers. Quadrel is proud to partner with some of the most respected and recognized companies affiliated with our industry.

Quadrel is a Connected Company

Quadrel has a culture structured to continually learn and adapt to a changing marketplace. With our Connected Company, Quadrel can distribute information and control very quickly. Imagine your Company with machinery connected to other machines and IT systems. Now imagine how efficient Connected Manufacturing can really be…